Printing Options

As the UK agents & stockists for Jokey Group for over 40 years, Taylor Davis Ltd are well equipped to offer a comprehensive range of polypropylene tubs & buckets.

Jokey Group continues to push the boundaries of packaging design and innovation, and are now among the market leaders in providing high quality in-mould label (IML) and digital print reproduction on their containers.

70 to 85 percent of all purchasing decisions are made spontaneously at the PoS. Whether in-mould labelling, offset or digital printing: the Jokey Design Service supports you in creating an effective packaging design.

We have put this handy guide together to give customers a better understanding of our printing options and the differences between them.

In-Mould Labelling

In-Mould Labelling (IML) is the more popular choice when it comes to packaging decoration, due to the high-quality look and feel with unlimited decoration and colour options.

The technology works by placing a pre-printed plastic film label into a mould and the label is seamlessly fused to the thermoplastic material during the moulding process. This integrates the production of the container and the labelling process which means faster production time and lower costs.

The container and label become a single waterproof, scratch-resistant unit and is 100% fully recyclable as it is one material. Set up costs are very reasonable as usually around £150 per design, per size. IML is available on tubs from 120ml including lids up to 35 litre buckets.

Features:

- Best Quality Available

- High Colour Authenticity

- Full Surface Decoration

- Good Durability

- Multi-sensory Effects

Digital Printing

Digital printing, also known as heat transfer printing is the method of which acustom logo or design is printed onto a transfer paper then the ink is transferred thermally onto a container using pressure and heat.

This method also provides a high-quality photographic and seamless finish. However, there are limitations on the coverage on the container. Set up costs are more expensive than IML but are still reasonable.

The digital print option is available on sizes 1.2 litre up to 35 litre buckets.

Features:

- High Quality

- Short Lead Times

- Low Minimum Order Qtys

- Suitable for Promotion

- Good Value for Smaller Quantities

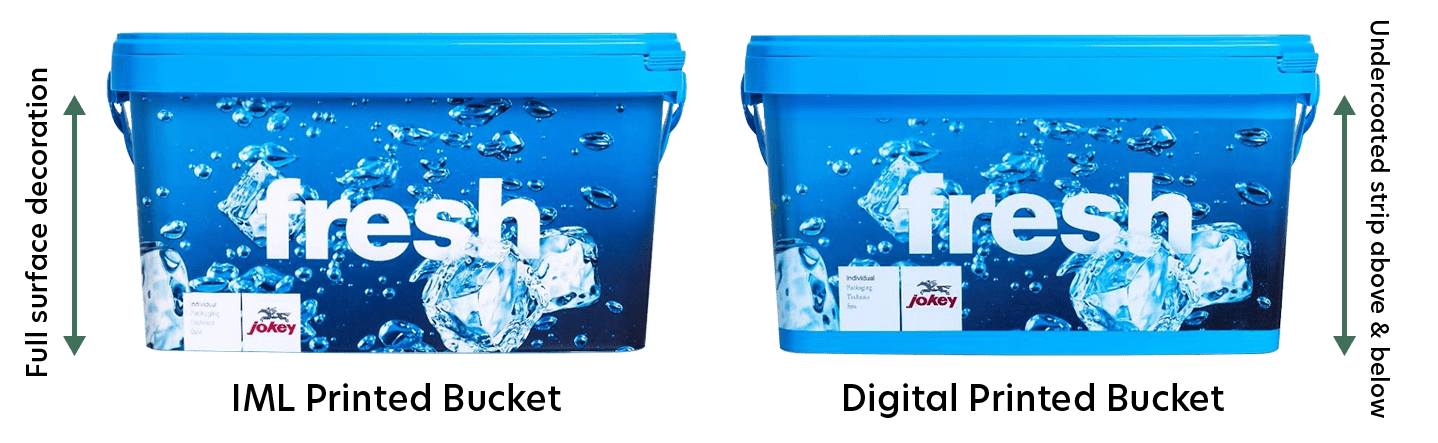

What are the main differences?

- IML printing allows the full container to be covered by the label from top to bottom, this is due to the production of the container and label being one singular process.

- Digital printing is limited to covering the main body of the container, leaving a gap at the top and bottom. This is because this process is carried out once the containers have already been produced.

IML | MULTISENSORY EFFECTS

See, touch, smell: Fascinating effects increase the value of your product and stimulate the consumer’s curiosity. Luminescent packaging materials, metallic and tinsel effects, black light function, peel off labels and much more increase the attractiveness of your packaging.